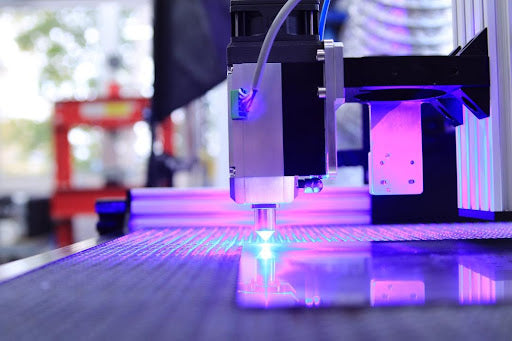

Winter CO2 Laser Antifreeze Coolant to Protect Your CO2 Machines

With the temperature dropping, make sure you take the steps you need to protect your CO2 laser machine. Your CO2 laser is a precision machine that needs proper care and maintenance to function in cold and freezing temperatures. You can get ready for the winter by using CO2 laser antifreeze laser coolant and taking additional steps to protect your investment. When you use CO2 laser antifreeze in your engraver, it can operate even in cold temperatures without damaging your machine. Antifreeze has a much lower freezing point than water, so it won't freeze or expand in your laser's tubes. You can operate your laser safely all winter long.

How Freezing Temperatures Damage CO2 Laser Engraving Machines

Your CO2 laser engraver depends on water flowing through the machine to provide proper cooling. All liquids have a freezing point. While many liquids contract when they freeze, water expands. If the water in your laser engraver expands, it can break the tubes in the water cooling system and seal connections, causing irreparable damage to your cooling system.

Why Do You Need to Protect Your CO2 Machine During Winter?

Laser machines operate best at approximately 25°C if you're running them at full power. Your laser tube is vulnerable to freezing and rupturing at low temperatures. If your laser tubes rupture, they can't be repaired, and this type of damage isn't covered under your warranty. CO2 machines need extra care during the winter so the delicate machinery that runs them isn't damaged. OMTech Antifreeze Laser Coolant is the best brand available to keep your CO2 laser machine running optimally all winter. OMTech Antifreeze Laser Coolant was developed specifically to run in OMTech’s CO2 laser engraving machines.

How Can You Take Precautions to Prevent Winter Damage?

If you won't be using your CO2 laser machine during the winter, drain water from the CO2 laser tubes. This will prevent it from freezing up and damaging the tubes. After you drain the water, clean the laser tubes with an air pump or air compressor. You should take any auxiliary equipment, such as chillers or pumps, indoors, where cold temperatures won't damage it.

If you want to continue using your CO2 laser machine during the winter, you should protect it with OMTech Antifreeze Coolant. The OMTech brand coolant will preserve the warranty on your machines, while using other brands can compromise your machine warranty. OMTech coolant effectively removes heat from the operating laser tube, which ensures your CO2 laser machine remains functional at an optimal temperature.

With OMTech Antifreeze, severely cold weather won't interfere with your CO2 machine's performance. It will continue to work at any temperature above −35°C. It also has anti-corrosion, anti-blockage, anti-boiling, and anti-flammability properties. OMTech's antifreeze has extremely low electrical conductivity, so you won't experience a drop in output power that can be caused by coolants with high electrical conductivity. However, it's not only the best option for OMTech CO2 lasers — it's also the best choice for every type of CO2 laser engraving machine on the market. You can rest assured that your CO2 machine will be protected no matter how cold your climate is.

Directions for Using OMTech CO2 Laser Antifreeze Coolant

For the best results, we recommend you use OMTech Antifreeze Coolant with OMTech's water cooler. The two were designed to be used together. When you use OMTech's water cooler, the entire water circuit is in a sealed state, which will reduce oxidation and reduce harmful dust and debris in your machine.

Clean your pipeline completely with deionized or distilled water. Unlike many antifreeze products, you don't need to dilute OMTech Antifreeze Coolant. You can use it full-strength. Check your specific CO2 laser engraver's manual for the exact amount to add. It's important not to exceed the listed amount since doing so can cause problems with your engraver's performance.

Precautions to Take With OMTech Antifreeze Coolant

OMTech Antifreeze Coolant is the best antifreeze product on the market for CO2 laser cutters. However, there are some precautions you should take to ensure you're using it safely and to its fullest advantage:

Use the Same CO2 Laser Antifreeze Coolant Throughout

It's important not to switch coolants or mix different brands. Although many contain the same major ingredient — ethylene glycol — the additives may differ. Mixing them could cause unwanted chemical reactions, precipitation, or bubbling.

Change Coolants With the Season

As it starts to warm up and temperatures are reliably above 0°C, clean your pipeline well and refill it with deionized or purified water for a coolant. If you are experiencing low temps for over three months, replace the OMTech Antifreeze Coolant every three months until the weather warms.

Advisable Not to Use Automobile Coolants

Antifreeze liquids made for automobiles have a high alkali pH level, and it may easily corrode the laser tube if used. If water mixture is added to dilute the coolant, the freezing point will rise and may no longer be able to protect your laser tube efficiently. The fluid viscosity of automobile coolants are also very high. When used in lasers, it may significantly reduce the flow rate of the liquid in the laser tube, reducing the heat exchange and cooling efficiency of the coolant. In addition, it may also easily cause pipe blockages as well. The electric conductivity of automobile antifreeze coolants are very high. Hence, the lifespan of your laser tube will be shortened under the presence of a strong electric field when your laser machine is in operation.

Use the Best Products to Get the Most Life Out of Your CO2 Machine

OMTech Antifreeze Laser Coolant was designed by OMTech engineers with the same attention to quality we put in our laser cutting machines. We have everything you need to get started or level up with laser engravers and cutters. Reach out today to find out more about our top-notch products.