Top 6 Tips for Laser Engraving Stainless Steel

Laser engraving stainless steel allows you to create beautiful, sleek products that will elevate your laser engraving hobby or business to the next level. From stainless steel keychains to stainless steel business cards, high-quality metal products are a great way to impress customers or loved ones!

Whether you’re customizing dog tags or tumblers, having a fiber laser engraver for stainless steel allows you to expand your product line to include personalized goods while expanding the customization of your products.

Before you start laser etching stainless steel, here are the top 10 essential tips for marking stainless steel.

Can Stainless Steel Be Laser Engraved?

Yes, not only can stainless steel be laser engraved, but it’s a great material for highly detailed and durable designs. From stainless steel tumblers, jewelry, tools, or even custom signs, the right laser engraving machine opens up a new world of projects, products, and potential!

What Is the Best Laser for Etching Stainless Steel?

The best laser engraver for stainless steel is a fiber laser engraver. This is due to the fiber laser’s wavelength, which is especially suited for engraving metals like stainless steel and provides deeper engraving, and more visible and long-lasting marks into the material.

While you can certainly opt to laser etch stainless steel with CO2 laser devices like the OMTech Polar 350 Laser Engraver, since the engravings made by these devices do not penetrate as deeply as fiber lasers, the end result is less durable.

Therefore, investing in a fiber laser machine for stainless steel laser engraving is your best bet for achieving high-quality and lasting metal engravings. With additions like OMTech’s MOPA Fiber Laser Machine series, you can even create colored markings on metal materials like stainless steel!

Top 6 Tips for Laser Engraving on Stainless Steel

Start with small projects

If you’re just starting out on stainless steel laser engraving, taking on a small project is a great opportunity to figure out the right settings for your laser engraver. This can start as a small test piece of scrap material or something more complex like stainless steel business cards. This will allow you to fine-tune the laser engraving stainless steel settings like speed, power, and focal height.

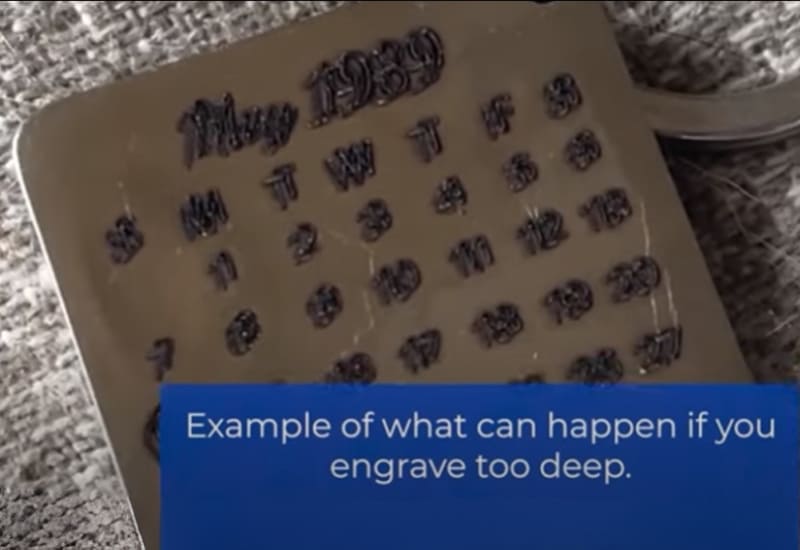

Play with the laser settings

If your test subject comes out looking less than ideal, you’ll probably want to play around with the settings to achieve optimal results. Sometimes, the laser power might be too high—resulting in fuzzy and indistinct engravings. If this occurs, reduce the power until the markings become clear.

Other times, you might get banding—an issue that leaves lines on the material and can ruin the markings. This is often corrected by a simple adjustment to the focus settings until the lines vanish.

Make sure your focal lens is clean

Debris or contaminants in your lens can cause issues with your engravings. Look out for variations like unclear images, lines, or other unwanted details coming through the etchings. This might be due to dirt or other particulates affecting the lens. You can clean your focal lens with a microfiber cloth or a lens-cleaning tissue and solution to fix this problem in no time.

Prep the stainless steel

Just like your focal lens should be clear, you should also ensure the surface of your stainless steel is clean before engraving. A pristine sheet leads to more accurate and precise engraving. Clean the stainless steel with a cleaning solution to make sure the surface is free of dust, grease, or other contaminants.

Clean the finished product

After you’ve finished engraving your stainless steel product, you might notice some discoloration or dark areas. By simply using a cleaner, it’s a matter of seconds to remove the dark spots and allow your finished product to shine! You can use an all-purpose cleaner, degreaser, or spot remover to polish off your stainless steel engravings.

Mark the appropriate focal height for different items

If you’re using your fiber marker to laser engrave stainless steel items in 2D and 3D, you should consider marking the focal heights for different objects. OMTech user, Kristina, from Kristhecreative, uses tape to mark the optimal heights for tumblers and 2D objects on her fiber laser engraver. This allows her to easily adjust the settings of the laser every time she switches projects!

Luckily, adjusting for focal height just got easier with OMTech’s newest Integrated Fiber Laser Marker with Autofocus. With this machine, finding the ideal focal height is as easy as pressing a button. Convenient features like autofocus allow you to start your projects with ease, making projects even faster!

Let Your Creativity Shine with OMTech!

Now that you have the knowledge to start laser engraving stainless steel, all you need is the right equipment! OMTech fiber markers like the MOPA and FM fiber markers allow you to create masterful results on a variety of metal materials. From crafting custom gifts for a loved one, or elevating the beautiful products from your small business, OMTech has you covered with the most reliable and precision laser engravers for stainless steel.

At OMTech, we’re not just about providing top-notch laser tech; we’re here to support you and your creativity! Check out our Facebook community to connect with other small business owners and laser enthusiasts. Our high-quality and affordable laser engravers offer the precision and versatility you need to turn all sorts of materials into works of art.

Why wait? Dive into the exciting world of laser engraving today and let your imagination—and OMTech—lead the way.