How to Choose a Right Fiber Laser Metal Cutting Machine

What is Fiber Laser Metal Cutting and Fabrication?

A fiber laser metal cutting machine makes cutting metal a snap. With a laser metal cutter, the types of projects you can take on and the ideas you can bring to life are virtually endless. We'll explain how laser metal cutting works, what to look for when choosing a new machine, and walk you through the features of OMTech's industry-leading FC fiber metal cutting machines.

Laser Metal Cutting and Fabrication Basics

Metal cutting is part of the metal fabrication process, which creates new metal structures, such as machines and component parts, by cutting, bending, and assembling metal into new shapes and formats. Industrial metal cutting machines are critical for precisely cutting thin sheets of metal to produce component parts for things we use every day, particularly electronics, automobiles, and medical equipment.

Metal is also laser cut to create circuit boards, casings for wires, car doors, hub caps, and much more. In the medical field, laser-cut metal is used to make hospital beds and gurneys, as well as surgical instruments and orthopedic pins, rods, and plates.

But, despite their importance to the industrial sector, laser cutters aren't just for large, professional metal shops. Today's metal laser cutters are compact and budget-friendly, making them accessible for businesses of all sizes. Thanks to these technological advances, small businesses and hobbyists can now use laser metal cutters to create unique items like intricate signs and plaques, accurate model buildings, stencils, coasters, keychains, ornaments, and even jewelry.

Investing in a laser metal cutter to do your metal cutting in-house is a surefire way to boost your business. Not having to send metal out to be cut by a third party boosts your profitability and puts you in control of your projects' timelines, eliminating wait times that can slow production. Having a laser metal cutter in-house also allows you to take on new types of projects and expand your business offerings, which increases your long-term return on investment.

CO2 Laser vs. Fiber Laser Metal Cutting Machine

There are two major types of laser metal cutters: Fiber and CO2 lasers. Both use intense beams of light to cut through metal and are far more powerful and expensive than metal engravers. CO2 laser metal cutters use oxygen, mirrors, and glass tubes to create and direct their lasers. Fiber laser metal cutters don’t require a support gas because they use rare elements, like erbium, ytterbium, and neodymium, to create an optical laser.

In order to decide which is best for you, consider what types of metal you plan to cut. Each type of metal has different properties that impact how it can be cut. CO2 lasers are excellent for cutting steel and stainless steel but can have trouble cutting aluminum and brass, which are both highly reflective. Fiber lasers are more powerful than CO2 lasers, so they can easily cut through most metals, and are especially good at cutting copper and aluminum.

Since CO2 lasers tend to be cheaper than fiber lasers, they are an excellent choice for small businesses and hobbyists planning to laser etch steel or stainless steel. If you want to cut a larger variety of metals, or need smaller and more precise cuts, a fiber laser may be worth the investment.

What to Look for in a Laser Metal Cutter

Whether you're cutting metal sheets, pipes, or stainless steel and aluminum rods, there is a laser metal cutter made for the task. There are four key factors to consider when choosing a laser fiber metal cutter: Working area, laser power supply, laser speed, warranty and service offerings:

- Working Area: Also known as bed-size, this is the size of the actual table used for cutting metal. Choose a working area that is large enough to fit the size of the metal you are working with but not so big that it is outsized for your space or needs. Make the most of the cutting surface by choosing an open-faced table model.

- Laser Power Supply: The higher the laser's power supply wattage, the more power the laser will have to cut through metal. More powerful fiber laser metal cutters come with higher price tags, so look for one that meets but does not exceed your needs so that you're not paying for more power than you'll actually use.

- Laser Speed: Laser speed is important to your productivity when cutting metal, but the laser's speed and power supply must be matched so that one does not outpace the other, which could damage the metal you are cutting.

- Warranty and Service: Protect your investment by choosing a reputable company that provides training on its machines and backs up its products with a substantial warranty and expert-level technical support.

Top Fiber Laser Metal Cutting Machines

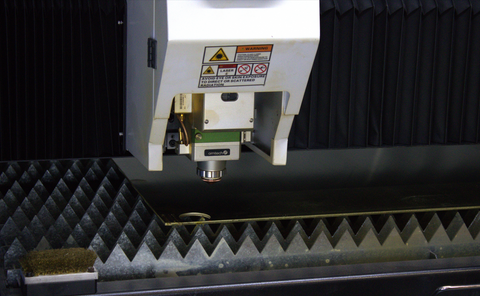

Based in Southern California, OMTech is an industry leader in fiber laser metal cutting. Each machine in its FC fiber laser metal cutter line offers a large working area and uses sawtooth working tables to ensure stability. OMTech's lasers are powerful, fast, precise, and efficient. With a range of 1.5 kilowatts (kW) to 3 kW, they are powerful enough to cut through stainless steel up to 8 mm thick.

OMTech uses German-manufactured IPG lasers, which have a high-quality beam, operate at a high frequency, and use high-quality materials. Unlike the Lightburn software found in other laser metal cutting machines, OMTech machines use Cypcut software. Cypcut dramatically simplifies complex machine operations and makes it easy to draw and cut a piece in just a few clicks. Importantly, Cypcut software allows you to nest your work before you cut so you can manipulate your project's design to optimize cutting space and avoid wasting materials. It also automatically optimizes errors when importing drawings, deleting duplicates, and smoothing curves to ensure you get a perfect cut.

OMTech's fiber laser metal cutters are built with safety and durability in mind. They are corrosion-resistant and include a smoke filtration system and transformer. They are also designed to be adapted to meet your particular needs. With OMTech, you can customize the laser strength and type for your machine and choose open- or closed-bed models to create the right fit for you.

Here is a snapshot of the features and capabilities of four machines in OMTech's FC fiber laser metal cutter line:

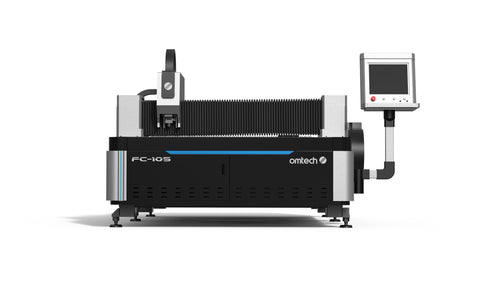

- OMTech FC-105C: This is the most cost-effective fiber laser metal cutter on the market for light metal fabrication. Its compact, all-in-one open-bed table configuration offers a 3 m x 1.5 m cutting area, a cutting speed of 666 mm/s, a precision of +/-0.05 mm, and the capacity to easily cut up to 12 mm of carbon steel sheets with its 1.5 kW IPG fiber laser.

- OMTech FC-44: If space is at a premium, the compact OMTech FC-44 is the machine for you. While it gives you a smaller footprint with its 1.3 m x 1.3 m sawtooth work-bed area, it does not skimp on highly precise metal processing. With a powerful IPG laser strength range of 1.5 kW to 3 kW, cutting speeds of 1333 mm/s, and a precision of +/-0.05 mm, the FC-44 can be used for light to medium-heavy metal fabrications, and is perfect for small to medium metal fabrication.

- OMTech FC-105: The most sought-after of the line, the OMTech FC-105 is of such high quality that it meets aerospace standards. It features a large, open-bed table with a 3 m x 1.5 m cutting area and also delivers lightning-fast cutting at 1333 mm/s with a precision of +/-0.05 mm. Designed to be customized for a variety of metal fabrication purposes, you can choose from a 1.5 kW or 3 kW IPG laser.

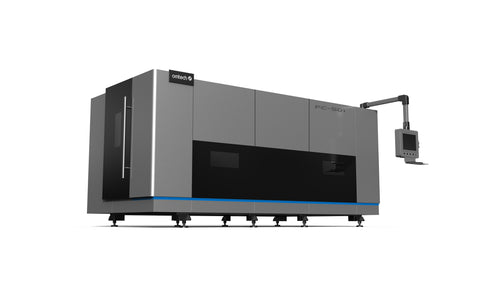

- OMTech FC-510: OMTech's top-end option for heavy metal fabrication, the FC-510, builds on the FC-105's flagship features to create a powerful and elegant machine designed to maximize safety. Its fully enclosed machine encapsulates debris and sparks while its pull-out platform makes it easy to get materials in and out of its 3 m x 1.5 m cutting area.

Why Choose OMTech

In addition to offering top-of-the-line quality and technology, OMTech backs up its products with outstanding customer support. When you buy from OMTech's FC line, you get free installation and three days of on-site training for your new machine.

OMTech also offers a top-notch warranty on its products, including lifetime, US-based technical support from experienced professionals. You also get a 30-day money-back guarantee and a two-year, full-service, bumper-to-bumper warranty to give you peace of mind and ensure you get the most out of your investment. With its easy financing program, which allows you to pay in installments, OMTech helps you put your new fiber laser metal cutter to work for your business right away.

Contact OMTech to learn more about its FC fiber laser metal cutter line and see how it can help your business soar.