A Guide To Laser Engraving Metal Business Cards

Business cards are essential for all professionals, regardless of industry or job title. They are a tangible reminder of you and your business, allowing potential clients or consumers to contact you and providing a valuable opportunity to foster a fruitful business relationship.

Your business cards offer a quick and easy method of exchanging information, and you can distribute them at any time or location. Metal business cards add a sleek and sophisticated look to your business, creating a great first impression on potential clients and prospects.

Why Choose Metal Business Cards

If you want to stand out from the crowd, laser-engraved metal business cards are an excellent choice. They are not only durable and long-lasting but stylish and unique. With their sleek and modern design, they are sure to catch the eye of anyone who receives one.

For your metal business cards, consider laser-etching on aluminum. This technique creates a smooth and precise look that is striking and elegant. Laser engraving allows you to create intricate and detailed patterns that are impossible with traditional printing methods.

Furthermore, laser engraving is a permanent process that will not fade or peel over time. This advantage means that your custom metal cards will look just as impressive years down the line, leaving a lasting impression on your clients.

Essential Tools and Materials for Laser Engraving Metal

To create memorable laser-engraved business cards, you'll need to first invest in a laser engraving machine. These highly specialized machines come in various sizes and power levels. The size you choose will depend on the size of the items you plan to engrave and how frequently you plan to use the machine.

Once you have your laser engraving machine, you'll need a computer with design software to create the artistic draft of your card. Programs like Lightburn allow you to create intricate images and graphics that you can engrave onto assorted materials, including metal.

In addition to your laser engraving machine and computer software, you'll also need a few other essential tools and materials to get started, including:

- Materials you can easily engrave, such as card stock and metal sheets

- Cutting tools to trim your layouts to size

- Metal laser marking powder to provide a higher contrast to your designs

Design Your Metal Business Cards

Designing your metal business cards is a critical step in establishing a professional and unique identity for your business or brand. The design you select should reflect your brand's personality and values. You can execute this phase yourself or seek help from a professional card design service to ensure your cards stand out and make a positive first impression.

When designing your business card, follow these steps:

- Choose the layout

- Select the material

- Consider the thickness of the material

- Contact professionals for help if necessary

Laser Engraving Process

Laser engraving is a precise process that melts the top layer of a material's surface with a laser beam, leaving a permanent mark. The beam removes material in a regulated manner, efficiently forging detailed etchings.

Advantages of Laser Engraving

The main reason you should use a laser-engraving machine to mark metal is that laser machines offer high precision and deep, long-lasting etchings—especially when utilizing a fiber marker for metal engraving.

By using a laser machine, you also have the opportunity to review your design on the software before starting the engraving process. This allows you to make changes and edits to the final product before committing it to the metal.

Running the Engraving Job

Before starting the engraving job, it is crucial to accurately adjust the laser engraver and machine settings. You must position the metal sheet correctly and optimize the laser parameters according to metal type and card thickness.

Next, calibrate the unit to ensure the engraving is accurate and precise. The actual etching process can take anywhere from a few minutes to several hours, depending on the complexity of the design, the size of the card, and the laser machine you’re using.

Quality Control and Inspection

Verifying the level of craftsmanship regarding your finished item is essential. To this end, quality control and inspection are necessities. To verify the quality of your card, carefully check your engraved surface for accuracy, uniformity, and overall quality.

Evaluate the production time, metal properties, and other factors to confirm the final product meets the highest expectations. If the results are not up to standard, you might have to adjust parameters like engraving speed and laser power. Play with the settings until you achieve the desired result!

Post-Processing for a Polished Look

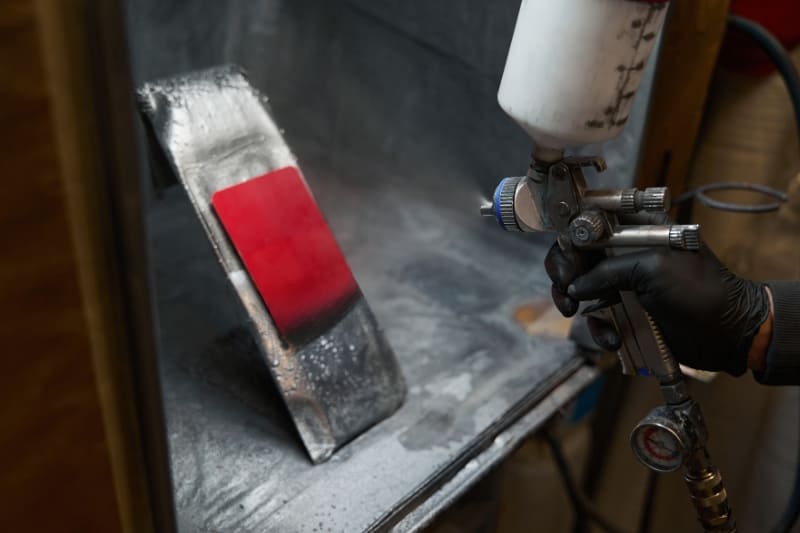

After you have concluded the engraving process, post-processing is necessary to give your metal business cards a polished aesthetic. This phase comprises cleaning the cards, removing any burrs or rough edges, and applying a protective coating to prevent scratches or damage. You can also color or paint your cards to give them a unique and personalized look.

Take the Next Step and Elevate Your Metal Laser Engraving

Investing in high-quality and efficient laser engraving machines can elevate your metal laser engraving experience. At OMTech, we offer a broad range of laser engraving machines that can fit any budget and tackle any job. We've designed our units to provide the finest attention to detail, accuracy, and efficiency.

With our laser engravers, you can create custom cards that will amaze your clients and attract more customers. Check out our selection of quality products and accessories today and join our awesome laser engraving community today!