Laser Etching Metal with CO2 Lasers: Use Metal Marking Powder!

Navigating the realm of CO2 laser engraving can be both exciting and challenging, especially if you don’t know where to start. If you’re looking to expand your laser etching expertise beyond the familiar mediums of leather, wood, and plastic, consider the world of laser etching metal.

Typically, a CO2 laser cannot penetrate bare metal, bouncing off the material without leaving any lasting impressions. What’s worse, the reflected CO2 laser can even damage your laser engraver’s protective cover, lens, and laser head, resulting in needless damage to your device. So, how can CO2 laser engravers mark metal?

Introducing OMTech’s Metal Marking Powder for Laser Etching Metal

In order to laser etch on metal, you’ll need a laser marking solution to coat the material. When the laser hits the laser mark solution, it bonds to the metal—creating a raised, black surface that perfectly displays your engraving pattern.

Enter the OMTech Metal Laser Marking Powder, a portable, compact resolution for metal laser engraving with a CO2 laser machine. At 4.1 fluid ounces per bottle, the metal marking powder is ideal for on-the-go use and easy storage. Simply add alcohol with a concentration of 99% or higher, and apply an even coat to the metal surface via spray or brush. Wait three to five minutes, and your metal product will be ready for laser engraving!

Store the remaining mixture in a cool, dry place away from sunlight to prevent the alcohol from evaporating. If the solution stratifies during storage, simply give it a good mix or add more alcohol. This laser-etching metal powder will be good to use over and over again! For only $24.99 per bottle or $94.99 for four units, you can save more by bundling.

Key Points for Laser Marking Metal

When it comes to laser engraving on metal, several factors can affect the quality of your metal engravings. Make sure to understand and follow these parameters for optimal results.

- Apply an Even Coating

During the application process, ensure that the marking powder is evenly distributed across the metal surface. Too thin of a coat will expose the metal and create an imprecise and unclear engraving pattern. If it is too thick, the laser will not be able to penetrate the solution and leave a lasting impression.

If you’re using a brush to apply the coating, you can thin out the solution by adding alcohol to adjust the thickness and concentration. If you’re utilizing a spray, apply the solution from left to right at a distance of about 8 inches away from the metal material for optimal results.

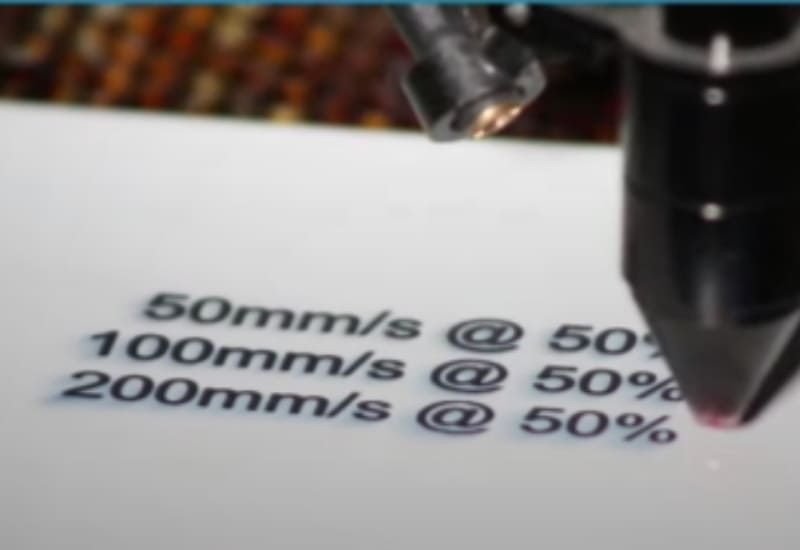

- Adjust Your Laser Engraving Speed and Power

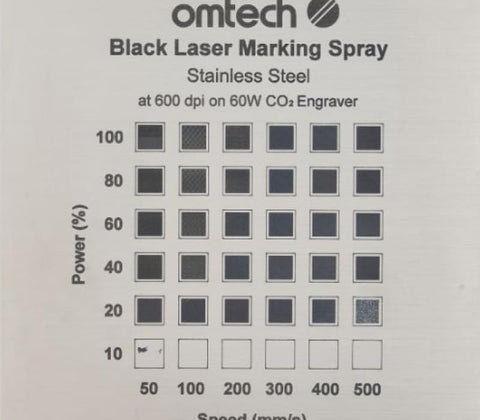

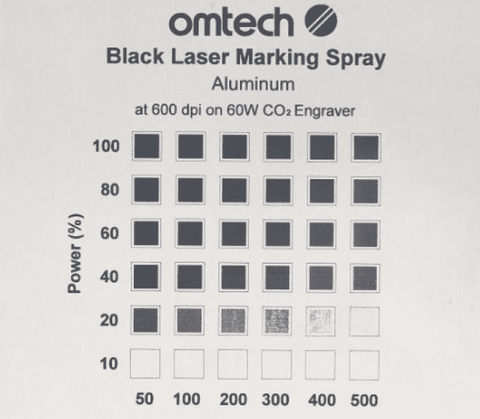

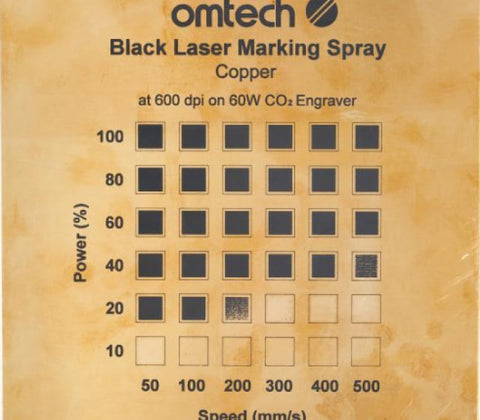

We recommend using a CO2 laser engraving machine of 25 watts or higher for the best results, like the OMTech Polar 50W or the MF1624 60W. If the power is too low, the laser may not be able to stimulate a color change from the metal marking powder.

When deciding the best settings for your laser marking machine for metal, refer to these charts. You should also test your laser engraver with the same metal you want to utilize to determine the optimal parameters. Generally, you should set your CO2 laser engraver to a speed between 100 to 300mm/s and power between 40 and 80% when laser engraving metal with our metal marking powder.

- Utilize Appropriate Line-Spacing/Pixels

This parameter determines your image quality. For a 60-watt CO2 laser engraver, the line intervals should be 0.2mm, 0.1mm, and 0.05mm from top to bottom. While you should choose the appropriate line spacing according to the size of the engraving image, it is important to note that if the image is too large and the spacing is too small, it may take a long time to engrave the pattern.

Dust Off Your CO2 Laser Machine and Start Laser Etching Metal!

Unlock the ability to laser etch metal with OMTech’s best CO2 laser accessories: laser metal marking sprays and powders. With our accessories, you can customize any metal objects once untouchable—stainless steel, aluminum, brass, iron, titanium, and more. If you’re considering capitalizing on your OMTech CO2 laser machine, you could start a small business making laser-engraved water bottles, laser-engraved jewelry, or anywhere your mind takes you!

Utilize the OMTech laser marking powder and take your laser engraving skills to the next level. With OMTech’s reliable, ultra-precise laser engraving technology and accessories, you have the power to create exceptional laser markings on metal. Browse our selection of CO2 laser machines and accessories today to make your dreams possible!