Extruded vs. Cast Acrylic: Differences in Characteristics, Manufacturing and Laser Cutting

Laser cutting acrylics can make some jaw-dropping products. However, not all acrylics are the same. Understanding the differences between extruded acrylic and cast acrylic can help you choose the best material for your project and achieve the finished result you want.

Cast vs. Extruded Acrylic: Characteristics and Manufacturing Process

Now, let's compare cast and extruded acrylic from their characteristics and manufacturing process.

Cast Acrylic

Cast acrylic is produced by mixing liquid acrylic monomers between two sheets of glass and processing them in a water bath or oven to form thick, rigid sheets. It also has excellent optical clarity and high light transmission—superior to many other plastics and even to glass in some respects.

It’s lightweight but stronger and more impact-resistant than glass. It doesn't shatter into sharp pieces like glass, so it’s often a popular application where safety is a concern.

The casting process is more time-consuming than extrusion but provides high-quality production with excellent control over the material's properties. You can create sheets with specific characteristics, including thickness, variety of colors, and transparency, that are remarkably durable and clear. Cast acrylic sheets are generally more expensive than extruded due to the more labor-intensive manufacturing process and the superior properties of the finished product.

Extruded Acrylic

Extruded acrylic is manufactured by mixing acrylic monomers with initiators that are pushed through a form or die to create sheets of varying thickness and size. These sheets can be continuously produced, resulting in consistent thickness but lower molecular weight compared to cast acrylic.

Extruded acrylic has excellent optical clarity and light transmission—comparable to glass—so it’s ideal if you need clear visibility. The extrusion process also allows for consistent control over the thickness of the acrylic sheets, so you end up with uniform thickness across the entire sheet, which is perfect for applications that require precision and uniformity.

While extruded acrylic sheets offer many benefits, they also have limitations. Compared to cast acrylic, they are susceptible to scratches and have lower resistance to some chemicals.

Key Differences in Laser Cutting Cast vs. Extruded Acrylic

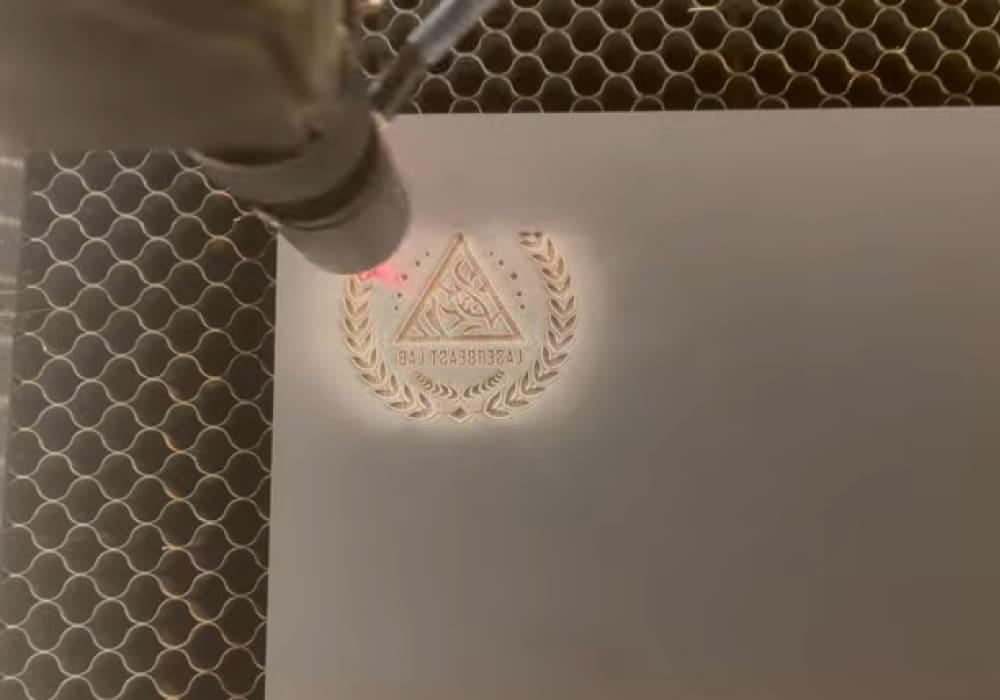

Laser cutting acrylic is a precise and efficient method for shaping acrylic sheets, widely used in various industries for its clean cuts and versatility. Extruded and cast acrylic behave differently under acrylic cutting machines due to their distinct manufacturing processes and physical properties. Some of the most significant differences in laser-cut acrylics include the following:

Cutting Speeds

Extruded acrylic material is generally faster to cut because its molecular structure—formed through extrusion—is less complex. The laser can more easily and quickly cut through the material, but the faster cutting process can leave a more ragged finish.

Cast acrylic cuts at slower speeds compared to extruded acrylic because of its higher molecular weight and acrylic density. The energy from the laser is absorbed more efficiently, so it requires more time to cut through. Despite the slower cutting speed, cast acrylic tends to produce a smoother and more flame-polished edge directly from the laser, which can reduce the need for post-processing.

Costs

Extruded acrylic is typically less expensive in terms of both raw material cost and the cutting process. Because you can cut it faster, you don’t have to invest as much in labor costs, and you’ll have faster production times. Because of this, it’s a cost-effective option for large-scale projects or when cost is a significant consideration.

Cast acrylic is more expensive than extruded acrylic, and the slower cutting speeds can increase production times and labor costs. The superior finish and material properties of cast acrylic may justify the higher cost if your project needs the highest quality and durability.

Finishes

The faster cutting speed of extruded acrylic can sometimes leave less smooth edges and may require additional processing to achieve a polished look. However, with optimal laser settings, good-quality cuts can still be achieved.

Cast acrylic produces smooth edges and a superior finish, often described as flame-polished, directly from the laser cutter. This high-quality finish is often preferred in projects where visual qualities are most important.

Applications

Due to its cost-effectiveness and the efficiency of cutting, extruded acrylic is a good choice for projects where budget and speed are primary concerns. It's commonly used for signs, general fabrication, and applications where the edge finish is not the main priority.

Cast acrylic is ideal for high-end applications where you need precision, superior optical clarity, and a flawless finish. Its excellent edge quality and durability are perfect for awards, retail displays, and any project where you need the highest-quality finished product.

Laser engraving or cutting acrylic has a wide range of applications, including:

- Signage and displays: Nameplates, awards, trophies, point-of-sale displays and more.

- Personalization: Home decor, personalized gifts, fashion accessories and more.

- Industrial applications: Product labeling, industrial parts, prototyping and more.

- Art and design: Sculpture, decorative items and more.

Which Material Is Right For You?

Whether you choose extruded or cast acrylic for laser cutting will depend on the cost, physical properties, production process, and the specific demands of your project.

- Finish: Cast acrylic is often the best choice if the project demands high-quality, aesthetically pleasing finishes with a glossy, flame-polished edge.

- Durability: Cast acrylic is a suitable material for applications requiring higher impact resistance, chemical resistance, or thermal stability. It's especially suited for outdoor use or environments where the material will be exposed to harsh conditions.

- Budget: If the project is budget-sensitive, extruded acrylic offers a cost-effective solution. Its lower material cost and faster cutting speeds help keep overall project costs down.

- Volume: Extruded acrylic might be more suitable if you're working on a large-scale project where efficiency and speed are top priorities. Its faster cutting speed can significantly reduce production time if you have tight deadlines or lower margins.

- Post-processing: If you want to minimize post-processing work, go with cast acrylic. You’ll get superior edge quality directly from the laser cutter.

Laser Cut With Ease With OMTech!

The type of acrylic or other material you choose will depend on what finished product you want to produce. OMTech’s high-quality acrylic cutting machines will give you good results regardless of your material. Don't miss out our latest series Pronto machines come with a significant upgrade in features, while maintaining a stylish design. With our acrylic laser cutter machines, you can create stunning products with acrylic, wood, metal, and more.

Find the perfect machine for your needs today and check the video below to know more about laser cutting acrylic.