Browse our wide collection of CO2 laser engraving machines which are also perfect wood engraving machines! From at-home desktop CO2 laser devices to high-powered CO2 laser cutting machines, find the best laser engraving machine for you here. Whether you're a DIY laser hobbyists or an experienced crafter with a booming laser business, OMTech laser machines deliver incredibly reliable laser engraving and cutting quality.

Check out our laser engraving accessories to go along with your CO2 laser machines!

OMTech Maker MF2028-80 90W CO2 Laser Engraving and Cutting Machine with 20" x 28" Working Area

OMTech Maker MF2028-80 90W CO2 Laser Engraving and Cutting Machine with 20" x 28" Working Area

OMTech K40+ 45W Desktop CO2 Laser Engraver with 8" x 12" Working Area and Detachable Honeycomb Workbed

OMTech K40+ 45W Desktop CO2 Laser Engraver with 8" x 12" Working Area and Detachable Honeycomb Workbed

OMTech Maker MF2028-100 100W CO2 Laser Cutter and Engraver with 20" x 28" Working Area

OMTech Maker MF2028-100 100W CO2 Laser Cutter and Engraver with 20" x 28" Working Area

OMTech Maker AF2028-80 90W CO2 Laser Engraver and Cutter with 20" x 28" Working Area and Autofocus

OMTech Maker AF2028-80 90W CO2 Laser Engraver and Cutter with 20" x 28" Working Area and Autofocus

OMTech Maker AF2028-60 60W CO2 Laser Engraver and Cutter with 20" x 28" Working Area and Autofocus

OMTech Maker AF2028-60 60W CO2 Laser Engraver and Cutter with 20" x 28" Working Area and Autofocus

OMTech Maker MF1624-60 60W CO2 Laser Engraving and Cutting Machine with 16" x 24" Working Area

OMTech Maker MF1624-60 60W CO2 Laser Engraving and Cutting Machine with 16" x 24" Working Area

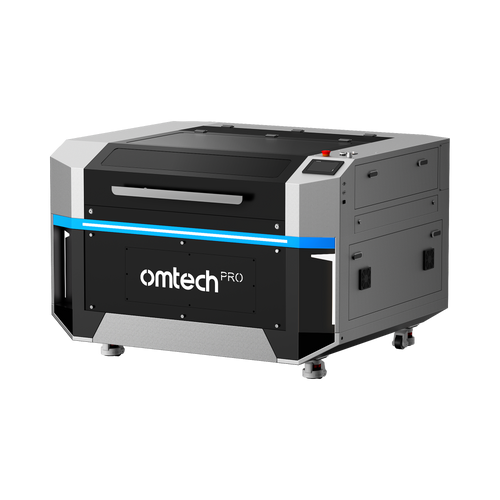

OMTech Pro 2440 80W/100W CO2 Laser Engraving and Cutting Machine with Autofocus and Built-in Water Chiller

OMTech Pro 2440 80W/100W CO2 Laser Engraving and Cutting Machine with Autofocus and Built-in Water Chiller

OMTech Maker AF4063-150 150W CO2 Laser Cutter and Engraver with 40" x 63" Working Area and Autofocus

OMTech Maker AF4063-150 150W CO2 Laser Cutter and Engraver with 40" x 63" Working Area and Autofocus

OMTech Maker ZF3551-130 130W CO2 Laser Cutter and Engraver with 35" x 51" Workbed and Dual Laser Tubes and Heads

OMTech Maker ZF3551-130 130W CO2 Laser Cutter and Engraver with 35" x 51" Workbed and Dual Laser Tubes and Heads

FAQ

The choice between autofocus and manual focus depends on your specific needs and preferences. Here's a breakdown:

Autofocus:

Pros: Convenient, especially for beginners. Automatically adjusts the focus for different material thicknesses.

Cons: Can be less precise than manual focus, especially for intricate details or uneven surfaces.

Manual focus:

Pros: Provides greater control over the focus point, allowing for more precise results.

Cons: Requires more time and skill to adjust the focus for each material and thickness.

Factors to consider when making your decision:

Frequency of use: If you're a beginner or only use the machine occasionally, autofocus might be more convenient.

Complexity of projects: If you're working on intricate designs or need the highest level of precision, manual focus may be better.

Budget: Manual focus systems are generally less expensive than autofocus systems.

Read this article for more information.

What materials can a CO2 laser engraver and cutter deal with?

CO2 laser engravers and cutters are versatile machines capable of working with a wide range of non-metallic materials. Commonly processed materials include:

Wood: Plywood, MDF, balsa wood, hardwood, softwood and more.

Acrylic: Clear, colored, and frosted acrylic sheets.

Leather: For creating custom designs and patterns.

Fabric: For cutting and engraving fabrics like cotton, denim, linen and more.

Paper and cardstock: For creating intricate designs and personalized items.

Foam: For prototyping and creating 3D objects.

Glass: For engraving designs onto glass surfaces.

...

Note: The specific materials a CO2 laser can process may vary depending on the laser's power, the material's thickness, and the desired outcome. It's always recommended to test with a small sample before processing a large piece.

Yes, CO2 laser machines are exceptionally well-suited for woodworking. They are considered as the best wood laser cutters and engravers with several advantages:

Precision: CO2 lasers can create intricate and detailed cuts and engravings with high precision.

Versatility: They can handle a wide variety of wood types and thicknesses.

Speed: Laser cutting and engraving is often faster than traditional woodworking methods.

Clean cuts: Lasers produce clean cuts with minimal burn marks or charring on wood.