OMTech Laser Cutter vs Cricut: Upgrade Your Cutting Machine

As a Cricut and Silhouette owner myself, I received this question time and time again: “Can you cut wood with that?” While there are some very thin woods and veneers that can be cut on a plotter, ideally, you’d want a laser for more capabilities. If you are finding yourself wanting to cut or engrave wood and acrylic, a laser cutting machine can be a great addition to your growing hobby or business. In this article, we’ll discuss the laser cutter vs Cricut comparison and show you how the two machines can work side by side. So whether you come from the world of Cricut, Silhouette, or another plotter, adding a laser engraver can help you offer bigger and better products and services and work in conjunction with your plotter on a variety of different projects.

This blog compares the capabilities of plotter cutting machines to CO2 laser cutting machines. Any product specifications mentioned reflect the official company offerings as of March 2022.

Is Cricut a Laser Cutter?

No, a Cricut is not a laser cutter. However, the two cutting machines work in similar ways. A Cricut machine is a cutting plotter that uses a computer-controlled blade to cut shapes out of thin materials. The blade height can be adjusted for various materials. However, the Cricut Explore cutting plotter can only cut up to 3/32 inches (2mm) deep.

What’s the difference between a Cricut and a Laser Cutter?

There are several differences between a Cricut and a laser cutter — the biggest difference being the cutting method. A Cricut uses a knife blade, while a laser cutter machine uses a thin laser beam to cut and engrave. Depending on the rated wattage, a CO2 laser cutting machine can cut wood, acrylic, and other materials up to ⅝ inch thick.

Should I Buy a Cricut or Laser Cutter?

Choosing between a cricut cutting plotter and a laser cutter machine really depends on your needs. Before you start searching for a machine that is better than Cricut, ask yourself what it is you really need for your projects:

- Which materials do I want to work with?

- How thick do I need to cut?

- Can it accommodate large projects?

Upgrade to a Laser Engraving Cutting Machine

You are probably familiar with cutting materials such as vinyl, cardstock, paper, faux leather, and stickers with your Cricut or Silhouette. What if you could add vinyl to your own hand-cut signs? Or use your faux leather with acrylic or wood accents in a new line of jewelry? When adding a laser engraver, it isn’t an either/or choice. It’s another tool in your arsenal to help your craft grow.

There are more steps to set up a laser cutter vs Cricut, such as ensuring you have the right precautions in place and the right setup for it. Ventilation is required, and the machine itself takes a lot more to set up initially than a cutting plotter. Also, keep in mind while it might be more involved, it will be well worth it once you can see what one of these machines can truly do.

Before I dive into the nitty-gritty details, let me go over some key points for you to think about as you read this article.

Cutting Machines & Budget

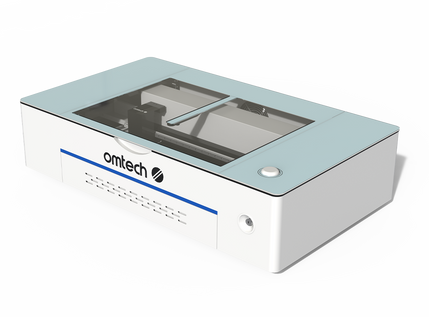

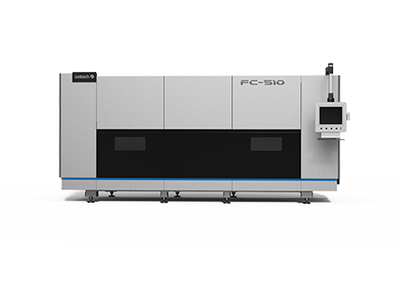

Starting with a Cricut vs laser cutter may seem like the cheaper option, but what if I told you there are laser cutters that are under $1,000? OMTech offers some small-scale machines that let you cut up to 8.5 x 11-inch material (wood and acrylic) that are just under the $600 mark, so you don’t need to jump on into a multi-thousand dollar unit right off if you don’t know if this is for you. You can always start small and get a larger machine later if you are worried about breaking the bank. Just keep in mind the smaller machines do use different software at the moment, although they can also be upgraded to use LightBurn.

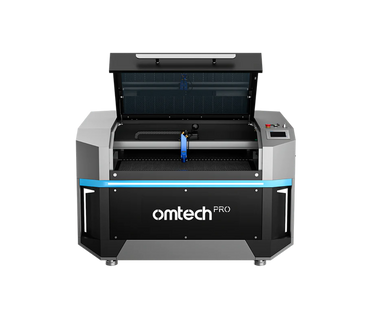

I personally went with the 60W laser cutter because I wanted a larger bed size and the ability to add a rotary, which would allow me to engrave mugs, glasses, and tumblers.

When you see something like 40W, 60W, 80W, this is pretty much the power that the machine can run at. The rule is the higher the wattage (which would be in the tube, which also connects to the power supply), the faster the speeds are and the thicker the material you can cut.

Cricut vs Laser Cutter: Materials

As with any new machine, you need materials to practice on. Wood and acrylic can be very expensive compared to things like paper, card stock, and vinyl. I always suggest purchasing seconds and misfits when possible.

Another thing to keep in mind is the materials you use with your plotter you cannot use with a laser, minus the card stock and paper. Vinyl and leather can give off poisonous fumes when cut, so the materials you purchase must be rated for a laser. There are laser-safe materials like laserable leatherettes, but you need to make sure that the item and product listing calls out safe for laser use.

Laser Cutter vs Cricut: Learning Curve

Whether you decide to add a laser or only keep your Cricut, make sure that you learn your machine, materials, and settings before you jump into selling. There is nothing worse than being hot off the press and finding out your earrings don’t stay together a few months later because of the glue you used. A lot of it is trial and error; adding a laser cutter to your Cricut workspace is an amazing addition!

Planning out your DIY Laser Cutter Workspace

A laser engraver takes up a lot more space and requires additional resources than that of a Cricut or other cutting plotter. Laser cutting machines are also a lot heavier and can range from 50 pounds up to several hundred pounds, depending on the size of the laser cutter you get.

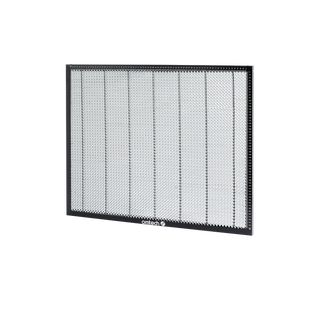

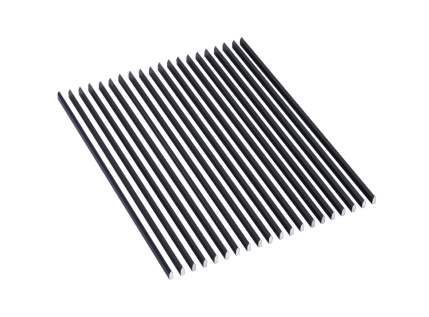

Each laser machine will come with the basic tools to get you started. This includes:

- Laser of choice

- Aquarium pump and a tub (this will keep your machine cool while it is running)

- Tubing (this allows you to vent the fumes out of a window, hole in the wall, and/or door)

- *You can purchase additional safety glasses if you so choose. Just make sure they are rated for CO2 laser.

A laser cutter is only part of it! If you wish to take your laser to the next level, you can also customize it with upgrades to help it run more efficiently. Some examples of upgrades include:

- Chiller (great if you plan on running your machine for many hours or if you live in a warm climate)

- Air Assist (allows for cleaner cuts with less burning and char. Requires an air compressor and various parts)

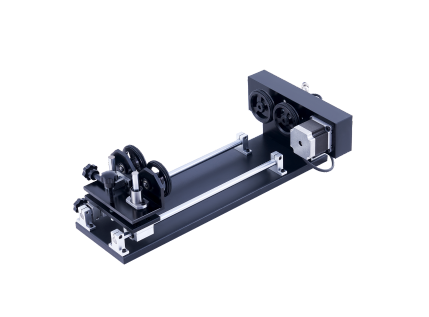

- Rotary (for engraving mugs and glasses)

- Inline fan (for pulling fumes out)

- Camera (There are two types- one that is used to line up your pieces and connects with the laser software LightBurn, and the second type would be to monitor your laser if you are not watching it)

Please note that a CO₂ laser cutting machine should never be left unattended! Whereas you can walk away while your Cricut is cutting, you cannot do that with a laser due to fire risk.

In addition to the laser machine and potential upgrades, you also need storage for new materials. Cardstock and 12x12 sheets are easier to fit and store than, say, 12x20 or 12x24 inch sheets of wood or acrylic.

Ask yourself these questions to give you an idea:

- How much can I budget for a new machine?

- What kind of product(s) do I want to make?

- Is this a hobby of business? (for business use, I recommend going with a 60W or larger due to the bed size and rotary option)

- How much space can I accommodate?

- Where would my laser be located? (a climate-controlled room would be ideal for preventing tube freezing)

- Do I have a window or area I can properly vent?

- What size bed do I want for cutting?

- Wattage?

- Do I want to add any upgrades?

Laser Cutter vs Cricut: Cutting Machine Software

Cutting machine software is probably the largest hurdle when jumping into the laser world. If you are used to Cricut, you are familiar with their cloud-based software and design functionality and the simplicity of a software that allows you to get from point A to B very quickly. If you have a Silhouette, you use Silhouette Studio, which allows more designing capabilities and options. There are a lot of people who still use Silhouette Studio to do their designing and then export the SVG to bring into LightBurn, the primary laser software of use. You can also use other programs to create SVGs as well, such as Inkscape or Adobe Illustrator.

LightBurn software doesn’t need the cloud, but it is more involved when it comes to understanding how it all works and comes together. There are new terms to learn, and the structure is very different when making the switch. Some of the terms to keep in mind include:

- Line (which means cut)

- Fill (which means engrave)

- Power (how much power you use when cutting/ engraving)

- Speed (how much speed you use)

- Lower power and higher speed = best for engraving, where as higher power and lower speed is best for cutting.

These settings are unique to each machine, however you can download various libraries from the OMTech Facebook group if you so choose.

You can also download a free trial of LightBurn to get a feel for it before you purchase your machine. Mind you, LightBurn is only compatible with select models. The 40W machines that OMTech sells (under $600.00) utilize a different software. These machines can be upgraded though!

Learning how to use a laser cutter

At the end of the day, it is a big commitment adding a laser to your hobby work and/or business, however it can be extremely rewarding. Not only will it add new products and services, but you can also use it in conjunction with your plotter — whether it be a Cricut, Silhouette, or a different brand.

How can I use a laser cutter with my Cricut plotter?

Here are a few ways you want use your laser cutter alongside your Cricut, or other cutter plotter machine:

- Use the laser to cut wood, use your plotter to cut vinyl and place it over the wood (great for signs)

- Cut out wooden earrings, use your plotter to cut faux leather, and wrap it around the earrings, truly creating unique, one-of-a-kind pieces!

- Use your plotter to cut fabric/ material (if you sew), and use your laser to engrave custom patches with names, logos, sayings, etc.

- Use your plotter to create custom packaging for laser cut products (stickers, header cards, promotionals, etc.)

These are just some ways you can use the two together. In fact, I use both my Cricut and Silhouette to create custom packaging and labels for my laser cut creations. It works great, especially for custom die-cut shapes.

There are also plenty of laser engraver resources available! Youtube has great free content to get you started, and there are great communities like the OMTech Official Facebook Group that can help provide insight into any questions and/or concerns that you may have. There are also free design files and libraries in the group if you feel overwhelmed.

Hopefully, this article has given you some insight into things to consider if you wish to add a laser cutter to your hobby or business. While this may seem overwhelming at first, anyone with the interest and patience to learn a new machine can learn how to laser engrave!